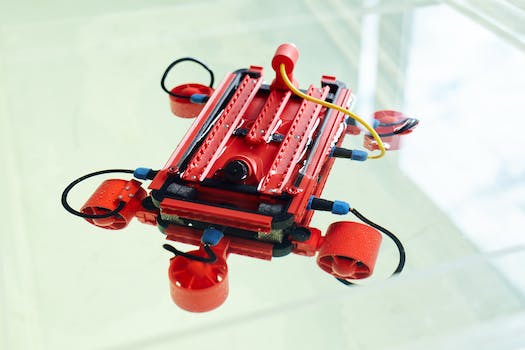

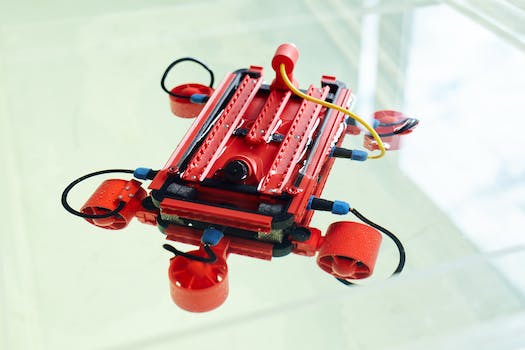

The Latest Innovations in the World of 3D Printing

-

Table of Contents

Introduction

The world of 3D printing is constantly evolving and advancing. From the early days of 3D printing when it was used mainly for prototyping and product development, to the current state of the art 3D printing technology, the possibilities are endless. In recent years, 3D printing has become increasingly accessible and affordable, allowing more people to explore the potential of this technology. This article will explore some of the latest innovations in the world of 3D printing, from materials to processes, and how they are being used to create amazing products. We will also look at the potential applications of 3D printing in the future and how it could revolutionize the way we create and manufacture products.

Exploring the Possibilities of 3D Printing in the Medical Field

The medical field is constantly evolving and advancing, and 3D printing is one of the most exciting new technologies to enter the space. 3D printing has the potential to revolutionize the way medical professionals diagnose and treat patients, and it is already being used in a variety of ways.

3D printing can be used to create custom prosthetics and implants that are tailored to the individual patient’s needs. This can be especially beneficial for patients who have complex medical conditions or require specialized implants. 3D printing can also be used to create models of organs and other body parts, which can be used to help surgeons plan and practice complex procedures.

3D printing can also be used to create personalized medications. This technology can be used to create medications that are tailored to the individual patient’s needs, which can help to reduce the risk of adverse reactions and improve the effectiveness of the treatment.

3D printing can also be used to create medical devices such as stents, catheters, and other implants. This technology can be used to create devices that are more precise and efficient than traditional methods, which can help to reduce the risk of complications and improve patient outcomes.

Finally, 3D printing can be used to create medical tools and instruments. This technology can be used to create tools that are more precise and efficient than traditional methods, which can help to reduce the risk of complications and improve patient outcomes.

3D printing is an exciting new technology that has the potential to revolutionize the way medical professionals diagnose and treat patients. This technology can be used to create custom prosthetics and implants, models of organs and other body parts, personalized medications, medical devices, and medical tools and instruments. As this technology continues to evolve, it is likely that it will become an increasingly important part of the medical field.

How 3D Printing is Revolutionizing the Manufacturing Industry

The manufacturing industry is undergoing a revolution, and 3D printing is at the forefront of this transformation. 3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects from a digital file. This technology has been around for decades, but it has recently become more accessible and affordable, making it a viable option for many businesses.

3D printing offers a number of advantages over traditional manufacturing methods. It is faster, more efficient, and more cost-effective. It also allows for greater customization, as objects can be designed and printed to exact specifications. This makes it ideal for producing complex parts and components that would otherwise be difficult or impossible to create using traditional methods.

3D printing is also more environmentally friendly than traditional manufacturing. It requires less energy and produces less waste, making it a more sustainable option. Additionally, 3D printing can be used to create parts and components from recycled materials, further reducing its environmental impact.

Finally, 3D printing is revolutionizing the way products are designed and developed. It allows for rapid prototyping, which means that products can be tested and refined quickly and efficiently. This reduces the time and cost associated with product development, making it easier for businesses to bring new products to market.

The manufacturing industry is undergoing a major transformation, and 3D printing is playing a major role in this shift. It is faster, more efficient, and more cost-effective than traditional manufacturing methods, and it allows for greater customization and rapid prototyping. It is also more environmentally friendly, making it a more sustainable option. As 3D printing continues to evolve, it will no doubt continue to revolutionize the manufacturing industry.

The Benefits of 3D Printing for Small Businesses

3D printing is revolutionizing the way small businesses operate. This technology is allowing entrepreneurs to create products quickly and cost-effectively, giving them a competitive edge in the market. Here are some of the benefits of 3D printing for small businesses.

1. Cost Savings: 3D printing is a cost-effective way to produce products. It eliminates the need for expensive tooling and molds, which can be costly for small businesses. 3D printing also reduces the cost of prototyping, allowing businesses to test out new designs without having to invest in expensive materials.

2. Speed: 3D printing is much faster than traditional manufacturing methods. It can produce complex parts in a fraction of the time, allowing businesses to get their products to market faster.

3. Customization: 3D printing allows businesses to create customized products that are tailored to their customers’ needs. This can help businesses stand out from the competition and increase their sales.

4. Versatility: 3D printing can be used to create a wide range of products, from toys to medical devices. This gives businesses the flexibility to create whatever they need, when they need it.

3D printing is a powerful tool for small businesses. It can help them save money, speed up production, create customized products, and be more versatile. If you’re a small business owner, consider investing in 3D printing technology to give your business a competitive edge.

The Impact of 3D Printing on the Environment

The advent of 3D printing has revolutionized the way we create and manufacture products. This technology has enabled us to produce complex objects quickly and cost-effectively, and it has opened up a world of possibilities for businesses and consumers alike.

However, as with any technology, there are potential environmental impacts associated with 3D printing. In this blog post, we’ll take a look at the environmental impact of 3D printing and what can be done to reduce it.

One of the most significant environmental impacts of 3D printing is the amount of energy it consumes. 3D printers require a lot of energy to operate, and this energy is often generated from non-renewable sources such as coal and natural gas. This means that 3D printing can contribute to air pollution and global warming.

Another environmental concern is the amount of waste generated by 3D printing. Many 3D printers use plastic filament, which is not biodegradable and can take hundreds of years to decompose. This means that 3D printed objects can end up in landfills, where they will remain for a long time.

Fortunately, there are steps that can be taken to reduce the environmental impact of 3D printing. For example, businesses and consumers can switch to using biodegradable filaments, which will break down much faster than traditional plastics. Additionally, 3D printers can be powered by renewable energy sources such as solar or wind power, which will reduce their carbon footprint.

Finally, businesses and consumers can reduce their 3D printing waste by recycling their 3D printed objects. Many 3D printing companies offer recycling services, which allow customers to send back their used 3D printed objects to be recycled into new products.

In conclusion, 3D printing has the potential to be an environmentally friendly technology, but it is important to be aware of the potential environmental impacts associated with it. By switching to biodegradable filaments, using renewable energy sources, and recycling 3D printed objects, businesses and consumers can reduce the environmental impact of 3D printing.

The Future of 3D Printing: What’s Next?

The future of 3D printing is an exciting prospect. With the technology advancing at a rapid pace, it’s hard to predict what’s next. However, there are a few trends that are likely to shape the future of 3D printing.

First, 3D printing is becoming more accessible. As the technology becomes more affordable and user-friendly, more people are able to take advantage of its benefits. This means that more businesses and individuals are able to use 3D printing to create custom products and prototypes.

Second, 3D printing is becoming more versatile. New materials and processes are being developed that allow for the creation of complex objects with intricate details. This means that 3D printing can be used for a wide range of applications, from medical devices to consumer products.

Third, 3D printing is becoming more efficient. Advances in software and hardware are making it easier to create complex objects quickly and accurately. This means that 3D printing can be used to create products faster and with less waste.

Finally, 3D printing is becoming more sustainable. New materials and processes are being developed that are more environmentally friendly. This means that 3D printing can be used to create products that are more sustainable and have a smaller environmental footprint.

These trends are likely to shape the future of 3D printing. As the technology continues to evolve, it will become more accessible, versatile, efficient, and sustainable. This will open up new possibilities for businesses and individuals to create custom products and prototypes quickly and accurately. The future of 3D printing is an exciting prospect, and it’s sure to bring about some amazing innovations.

Conclusion

The Latest Innovations in the World of 3D Printing have opened up a world of possibilities for businesses and individuals alike. From rapid prototyping to custom manufacturing, 3D printing has revolutionized the way we create and manufacture products. With the continued development of 3D printing technology, the possibilities are endless. 3D printing is a rapidly growing industry that is sure to continue to revolutionize the way we create and manufacture products for years to come.